Behind the Scenes with Gogo’s Field Service Engineers

February 10, 2026

The call came in just after sunrise. A flight crew in Texas had noticed intermittent connectivity during preflight checks, with passengers scheduled to board in a few hours. While Gogo’s 24/7 Technical Support team dug into the data remotely, a Field Service Engineer was already grabbing tools, coordinating with the hangar, and mapping out next steps. By the time the aircraft was fueled and ready, the issue was resolved—no delays, no drama, just another quiet win for a team most passengers never see.

That’s a day in the life of Gogo’s Field Service Engineers (FSEs).

When an aircraft’s connectivity needs attention, FSEs are the ones who roll up their sleeves and make things happen—on the ramp, in the hangar, or occasionally even mid-flight. These seasoned pros ensure Gogo systems stay reliable and ready through hands-on troubleshooting, installations, and real-time training for flight departments around the world.

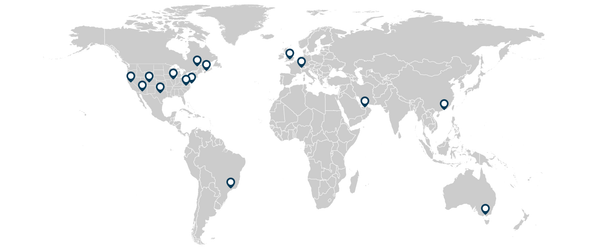

With 35 engineers strategically based across North America, Europe, APAC, and Latin America, Gogo’s FSE team delivers global coverage and can often arrive on-site within 24 hours. Their mission is simple: keep customers connected while minimizing aircraft downtime.

The Go-To Crew for Connectivity

Most inflight connectivity questions are resolved quickly through Gogo’s 24/7 Technical Support line. But when a situation calls for hands-on expertise, the FSEs step in as the boots-on-the-ground specialists.

Their work spans everything from installing and troubleshooting inflight Wi-Fi systems to performing predictive cabin analysis and Wi-Fi mapping for optimized signal performance. They run VSWR and cable integrity tests, conduct bonding checks, troubleshoot ARINC 429 systems, and provide tailored on-site training and operational analysis for flight departments.

No two visits look the same. One day might involve fine-tuning a network configuration; another could mean running flight tests or walking a crew through system operations. FSEs adapt to each operator’s schedule and often partner closely with Gogo’s Entry into Service team to ensure new systems are introduced smoothly and confidently.

Speed, Savvy, and a Global Footprint

Behind every successful dispatch is a tightly coordinated effort. Nearly 98% of issues are resolved remotely thanks to proactive monitoring and close collaboration with Gogo’s call-in teams. But when tools hit the tarmac, regional FSEs can typically be on-site within 24 hours—sometimes sooner if the aircraft is near one of Gogo’s base locations.

Communication stays personal and efficient, whether it’s a phone call, an email, or even a WhatsApp message. And while the FSE may be the face customers see, they’re backed by a global network that includes the Network Operations Center, dealers, OEMs, and engineering teams—all working in sync to keep aircraft flying and data flowing.

Proactive by Design, Productive by Nature

What truly sets Gogo apart is how proactive the system is by design. Over-the-air updates, continuous monitoring, and seamless coordination between the Network Operations Center and FSEs often identify and resolve potential issues before customers ever notice. The result? Less downtime, fewer disruptions, and smoother operations.

And when unplanned issues do arise, the FSE team’s years of combined aviation experience shines through—solving problems swiftly, intelligently, and always with the customer’s schedule in mind.

Keeping You Connected—From Hangar to Horizon

From testing Wi-Fi performance in Texas to troubleshooting systems in Toulouse, Gogo’s Field Service Engineers are more than troubleshooters. They’re trusted partners, quietly working behind the scenes to keep aircraft connected and passengers productive.

It’s not always glamorous, and it’s rarely noticed—but when connectivity just works, chances are an FSE helped make it happen.